Cosmetic

Polylactic Acid (PLA)

In the realm of consumer 3D printing, polylactic acid (PLA) is king.

First and foremost, PLA is easy to print with and it doesn’t warp as easily. Meaning it opens the door to easily print larger and or more complex geometries at a lower cost partially due to its great bridging and overhang qualities.

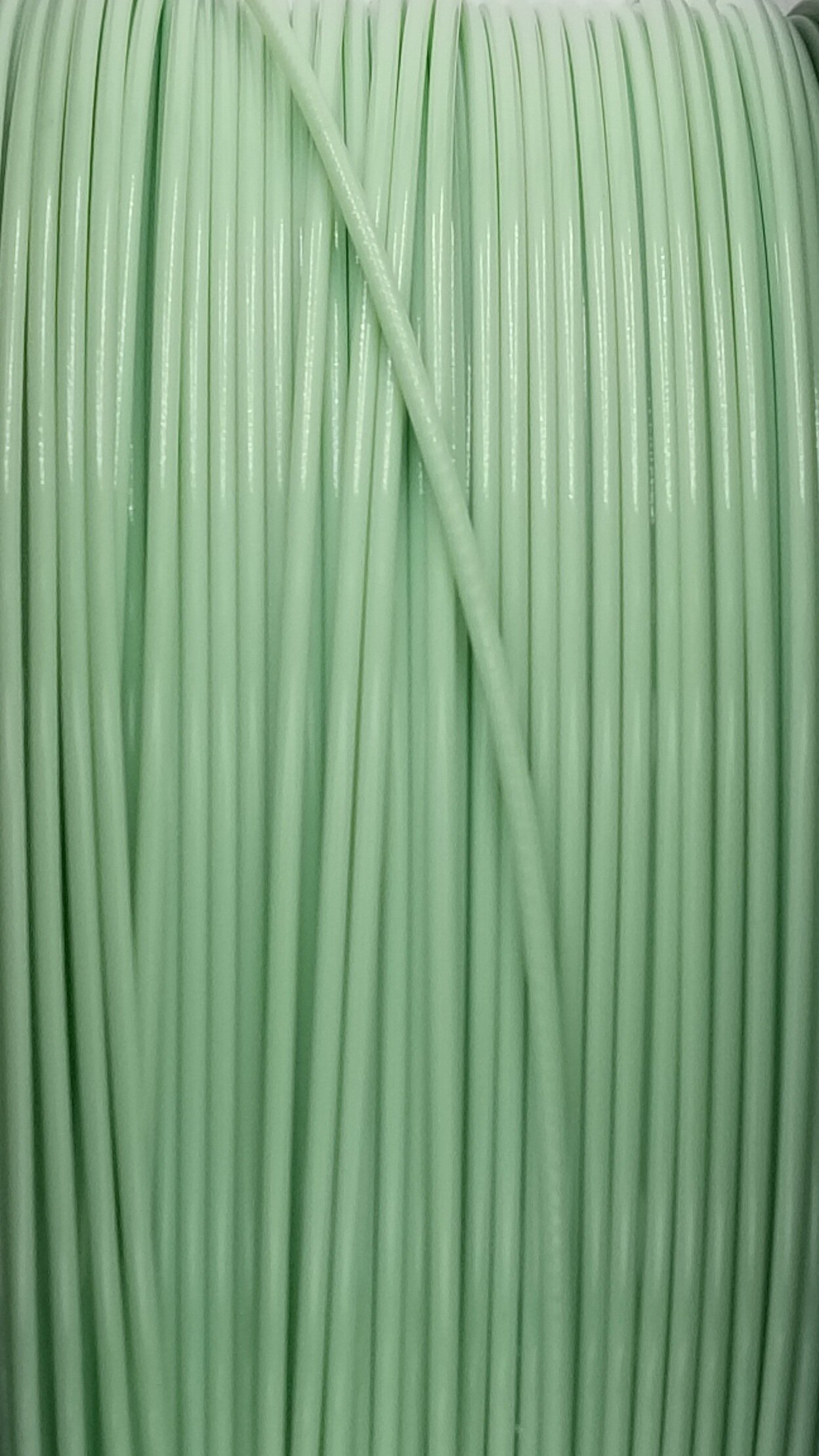

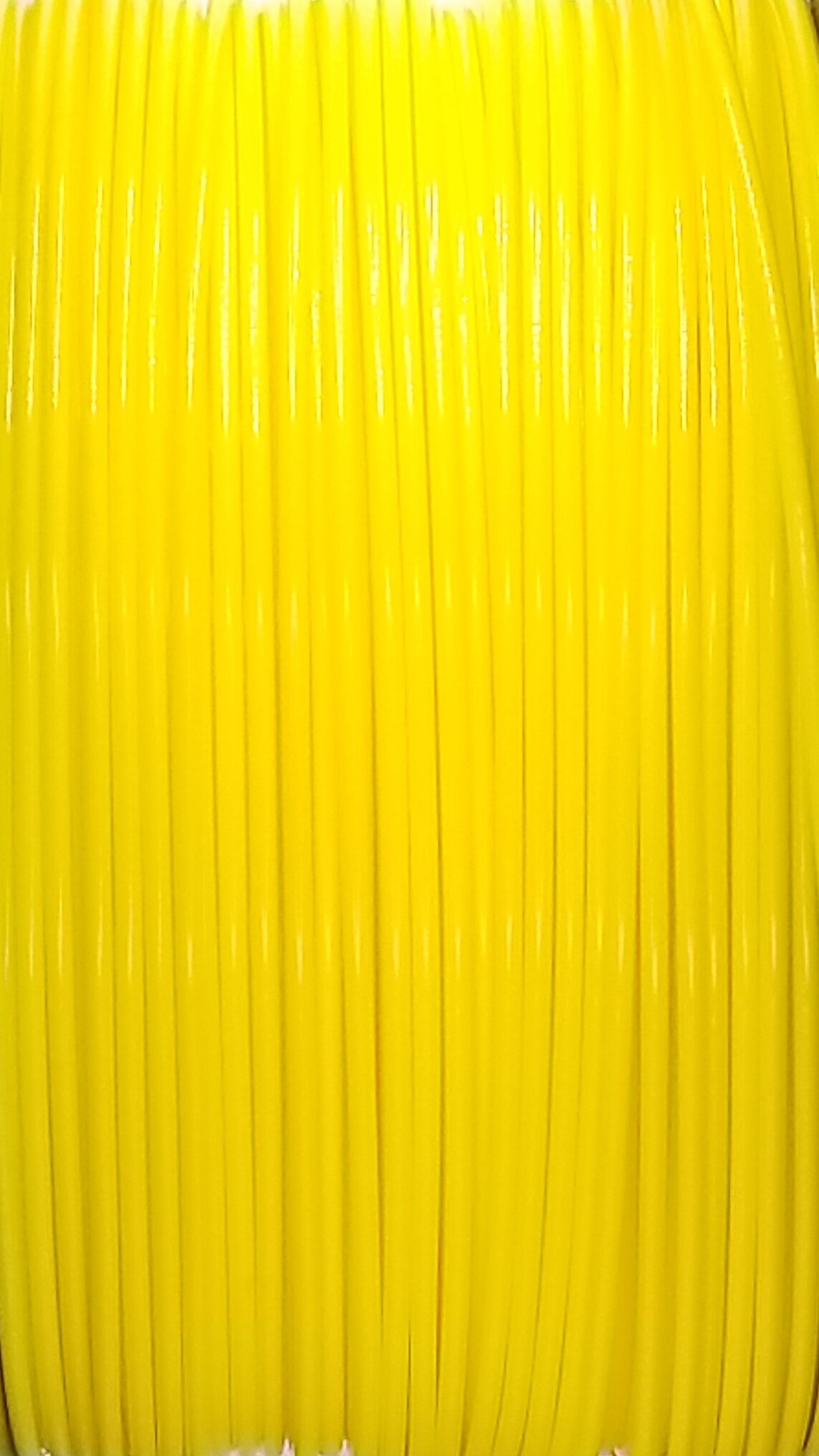

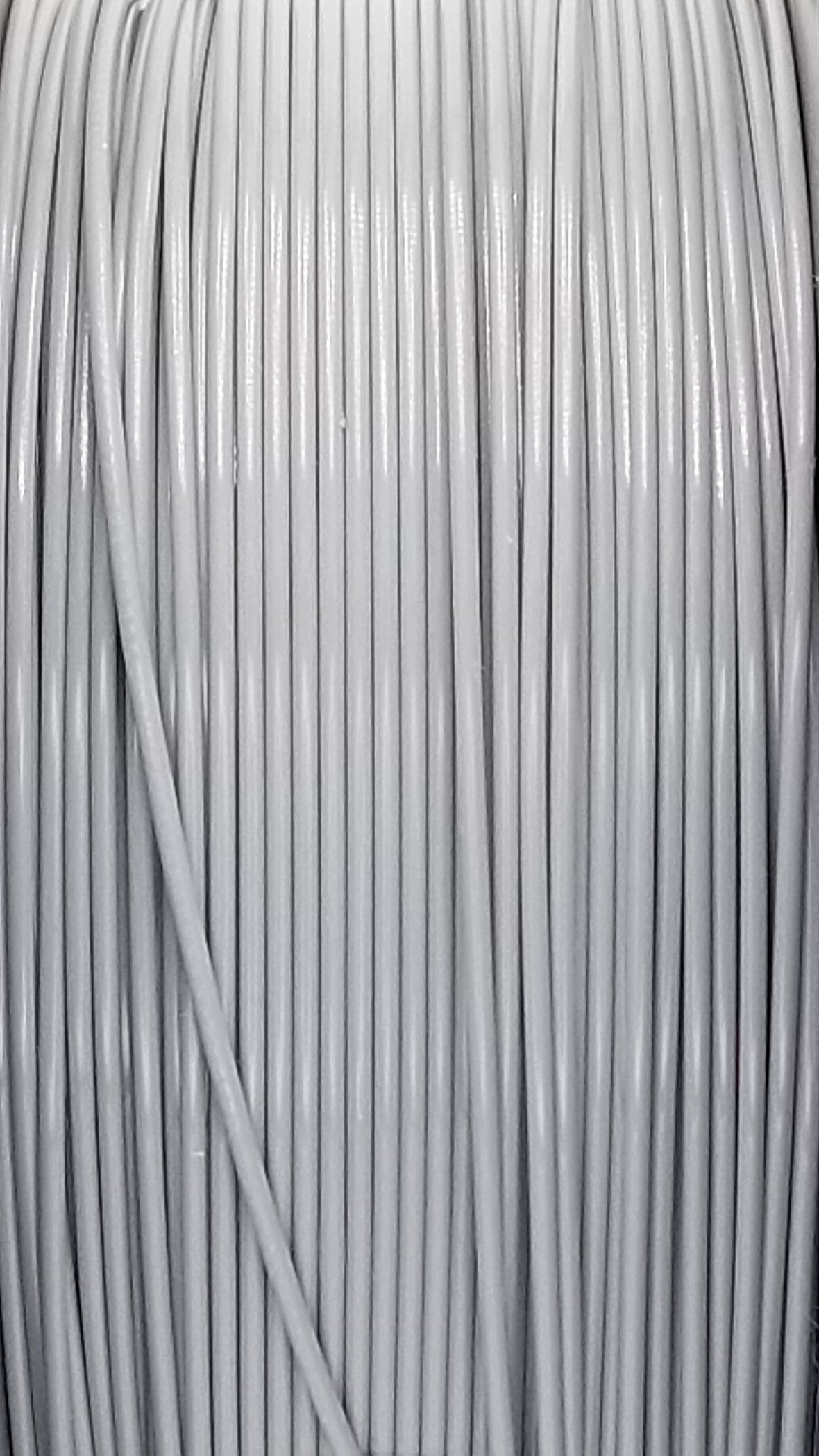

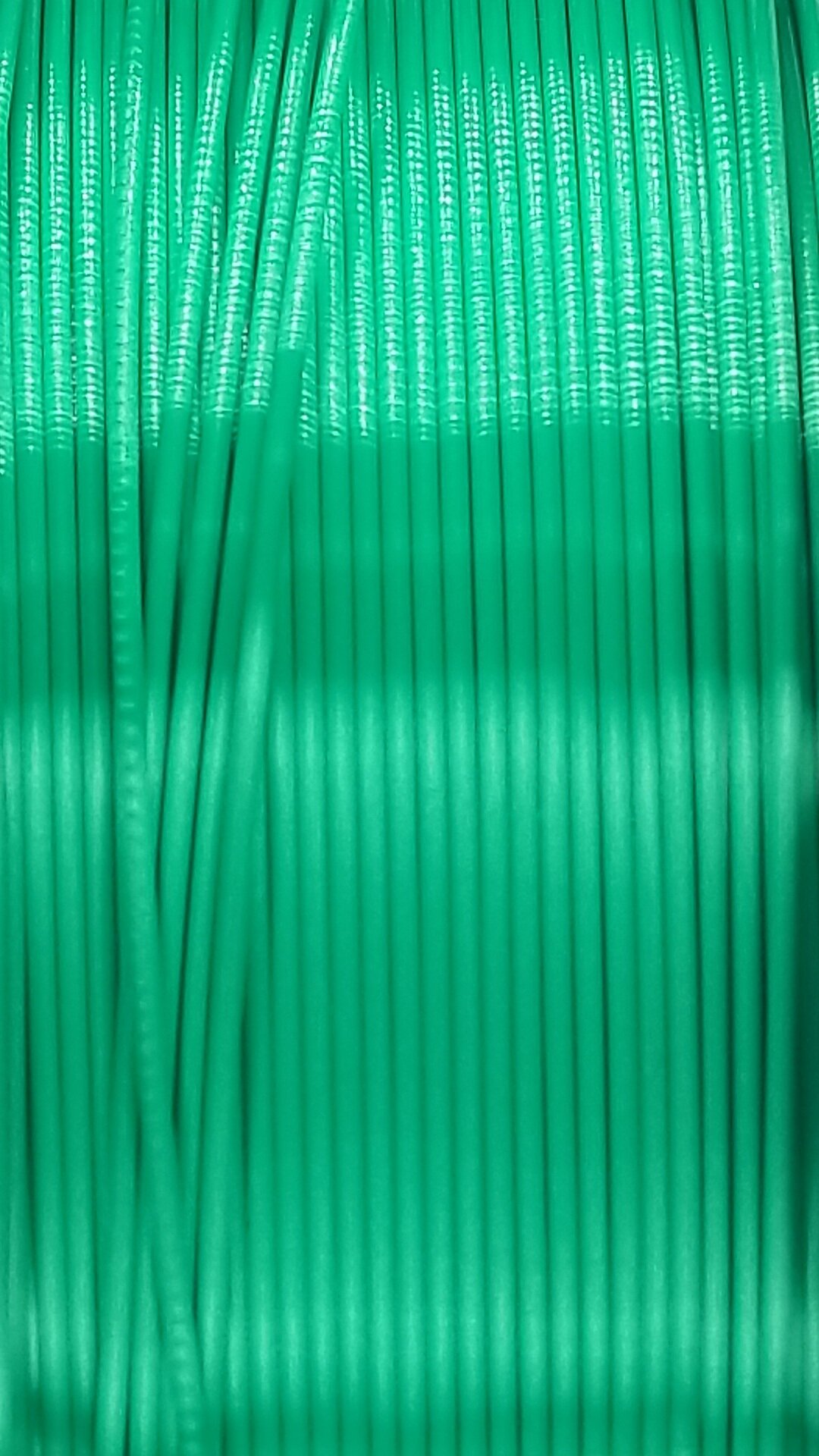

However, one of the most appealing aspects of PLA is that it has a huge range of colors and effects to choose from with nearly an endless abundance of colors and styles.

As you scroll below, you’ll start with:

Standard colored PLA’s

Glow in the Dark PLA’s

Metal-like in color Silk PLA’s

Unicorn PLA’s

Rainbow PLA’s

Metal Powder Infused PLA’s

Finally, as a biodegradable thermoplastic, PLA is more environmentally friendly than most types of 3D printing filament, being made from annually renewable resources such as corn starch or sugar cane.

General Properties:

Strength: Stiff & Brittle

Flexibility: Poor

Heat Deflection Temp: ~130°F (55°C)

Tensile Modulus (X-Y): ~1997 MPa

Tensile Strength (X-Y): ~23 MPa

Elongation at break (X-Y): ~28%

Bending modulus (X-Y): ~2209 MPa

Bending strength (X-Y): ~40 MP

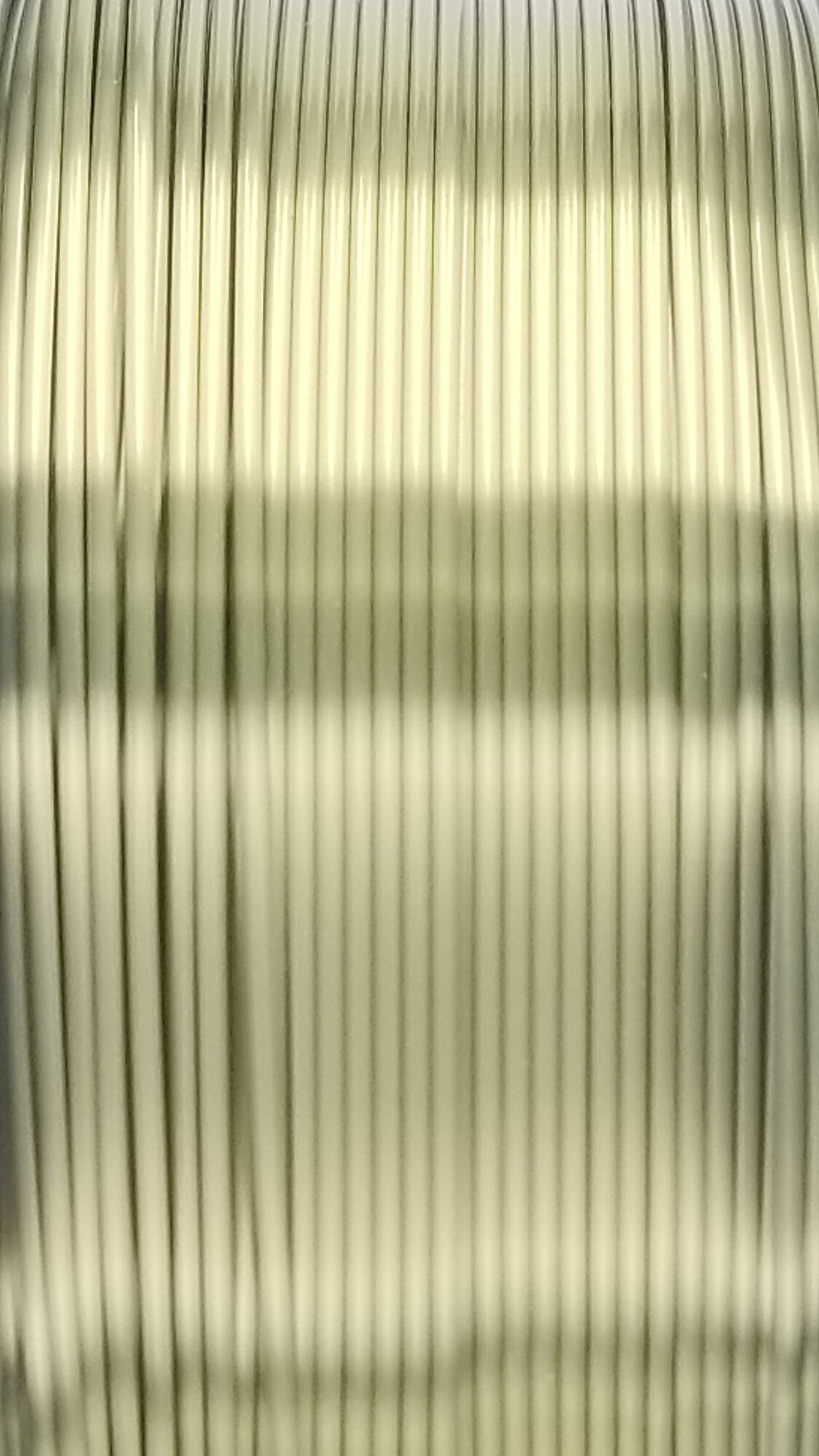

Silk PLA

Similar properties as PLA, however these will show an extremely high gloss finish giving a metal-like look to your parts. However, this blend will have increased brittleness and will loose its shine under UV exposure.

Unicorn PLA’s

These are rare and majestic PLA’s with added shimmer, shine and sparkle with a touch of translucent gloss. Pictures do not justify and we are working on providing more examples as this is a newly added option and here for a limited time.

Rainbow PLA’s

These rainbow spools of material are made while mixing different colored PLA pallets which produce a transition from color to color. Don’t let the images fool you, it takes a large amount of filament to see the transition from color to color, but when it does its give an awesome rainbow effect. Plus, it is impossible to replicate the same print with such changes in color that will give you a one-of-a-kind product! More options are available that are not shown, if interested, please let us know.

Metal Infused High Temp PLA (HTPLA)

Proto-pasta metal-filled composite HTPLA is a combination of high-quality metal powder & high-performance PLA. The result yields 3D printed prototypes & finished parts with metal-like properties. Mill, brush, polish, or patina for a personalized finish. We may Heat Treat your part for use up 160°C (320°F) in demanding applications.

You may mill, brush, polish or patina to finish although not required.

What is HTPLA & Heat Treating? HTPLA is a semi-crystalline grade of PLA optimized to survive heat treating (also known as annealing) for higher temperature use. Standard PLA loses form past 50°C - 60°C (120°F - 140°F) because amorphous materials see significant loss of stiffness at glass transition. Heat treating creates a crystalline structure allowing HTPLA to maintain useful Stiffness up to 160°C (320°F) depending on application, form, load, or other conditions. This increases the usefulness of heat treated HTPLA over standard, amorphous PLA.

General Properties:

Heat Treatable and Annealable

Weight: 60% metal by weight

Appearance: Mill, brush, polish or patina is optional

Corrosion: Can Rust

Strength: Stiff & Brittle

Flexibility: Poor

Carbon Fiber PLA (CF PLA)

PLA with a 20% mixture of real chopped carbon fibers. Similar properties as PLA but with Carbon Fibers, A stronger, sturdier and more dimensionally stable version of PLA. Printed parts show an excellent surface finish with low layer line visibility and an increased dimensional accuracy.

Appearance is similar to Matte Black filament however, with an added slight shine of Carbon.