Materials & Colors

(CNC Machining Coming Soon!)

Aluminum, Stainless Steel, Alloy Steel, Mild Steel, Tool Steel, Spring Steel, Titanium, Brass, Copper

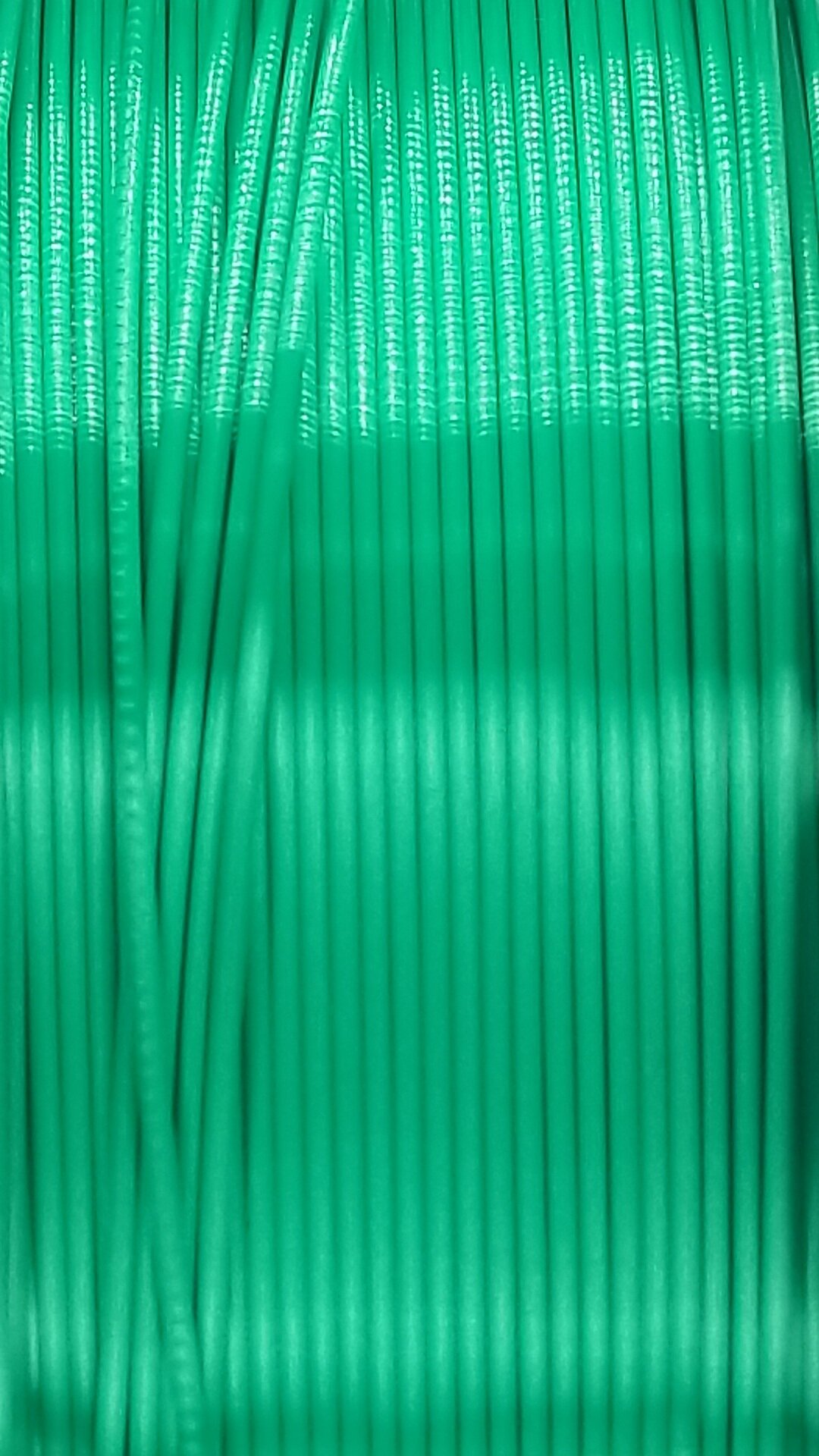

Cosmetic

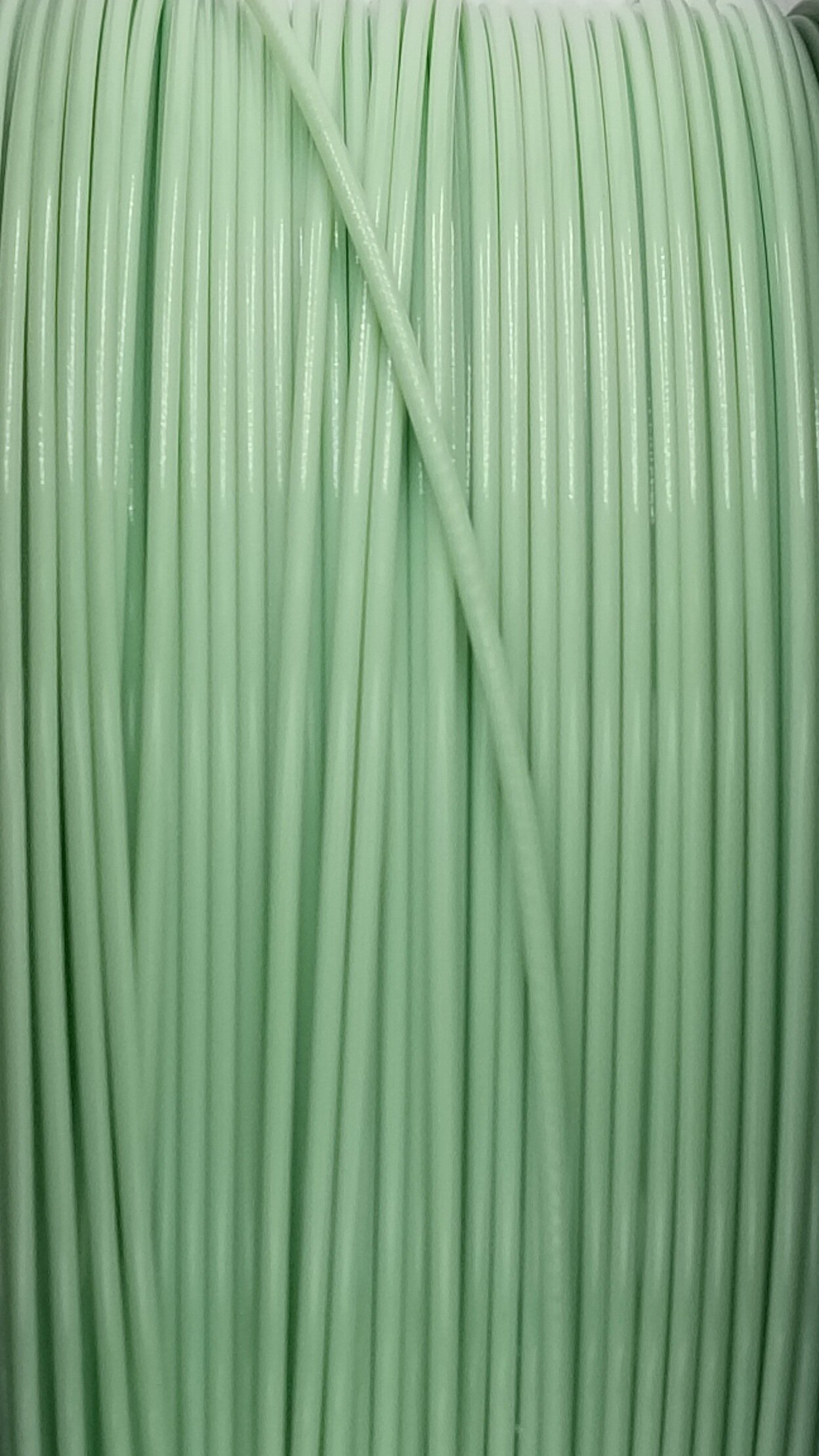

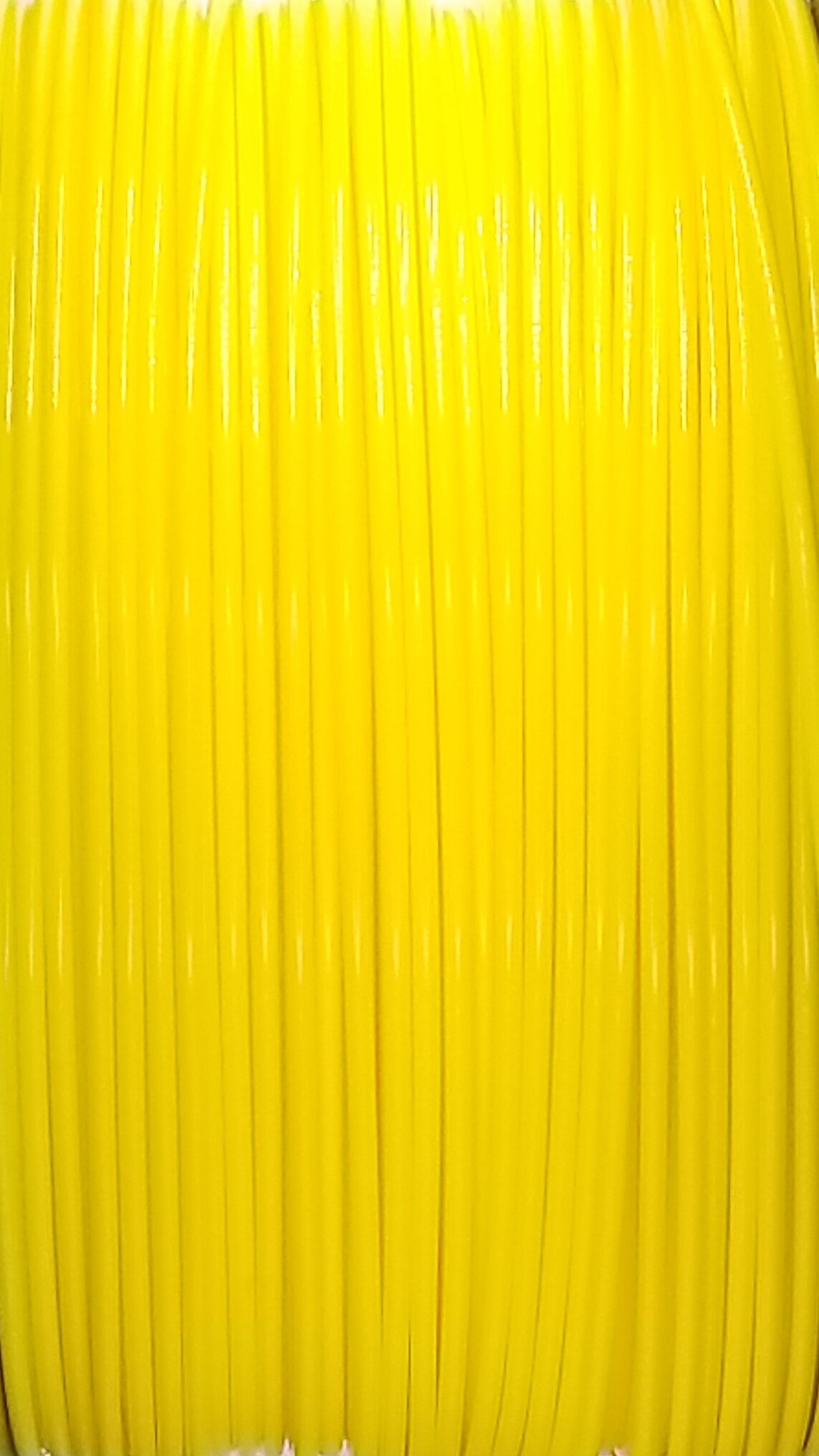

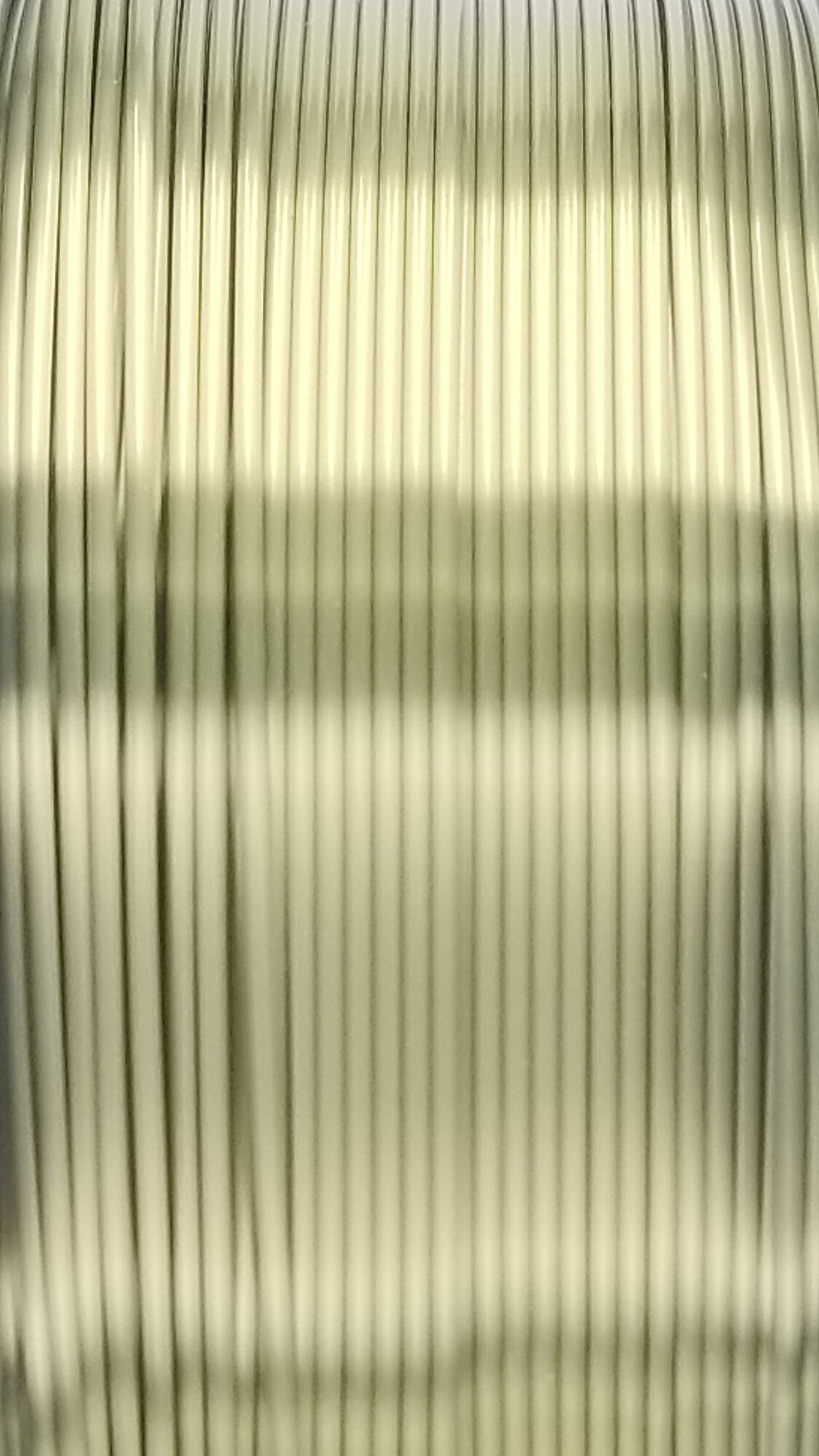

Welcome to the dynamic and versatile realm of cosmetic rapid prototyping using Polylactic Acid. This material is commonly referred to as PLA and presents an extensive array of vibrant colors and shimmering blends, including but not limited to:

A wide spectrum of color options

High-gloss metallic-like Silks

Galaxy or glitter-infused blends

Real metal powder infused blends

Dual and tri-color blends

Glow-in-the-dark blends

Carbon fiber-infused blends

ESD blends

*Thermal Properties:

Heat Deflection Temp: ~130°F

Commodity

The entry-level to functional prototyping characterized by materials with a higher capacity to endure elevated temperatures, ability to resist UV exposure and enhanced mechanical durability when compared to PLA’s.

Various color spectrum

Limited high-gloss metallic-like blends

Galaxy or glitter-infused blends

Carbon fiber-infused blends

ESD blends

Improved UV resistance

Improved impact resistance

Improved heat resistance

*Thermal Properties:

PETG Heat Deflection Temp: ~170°F

ASA Heat Deflection Temp: ~(210-220)°F

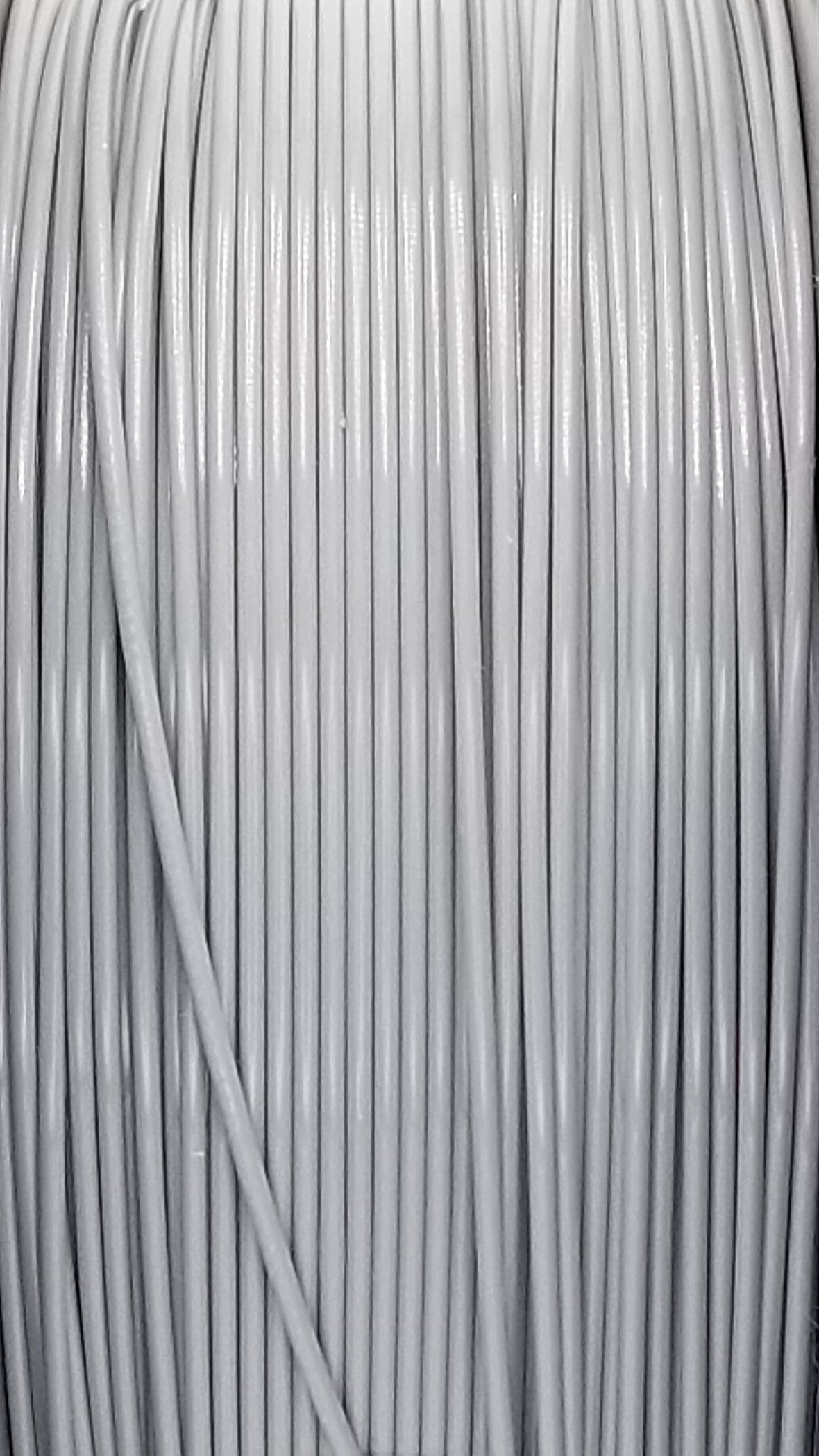

Engineering Grade

We now transition into the domain of Engineer Grade plastics, distinguished by superior mechanical and thermal properties compared to their counterparts in lower tiers.

Limited color spectrum

Carbon fiber-infused blends

Glass fiber-infused blends

Flexible options

ESD blends

Improved UV resistance

Improved impact resistance

improved heat resistance

Improved chemical resistance

Aluminum 5052 replacement

*Thermal Properties:

TPU Heat Deflection Temp: ~140° F

PC Heat Deflection Temp: ~(225-275)° F

PCTG Heat Deflection Temp: ~170° F

PA’s Heat Deflection Temp: ~(230-430)° F

CNC Machining

5 and 3-Axis Milling and Turning now available with the supplied or in-house produced CAD model. Various grades of engineering and decorative metals with various optional finishes, threading, inserting and part marking with a default tolerance IAW ISO 2768-1 allowing us to provide highly competitive pricing (tolerances ranging from +/- .004”- .079” depending on part size).

Perfect for obsolete part replacement, prototyping, single part production or small batch production (quantities of 1-100 parts).

Other materials also include plastics, high performance polymers and carbon fiber.

Aluminum (6061, 7075, 5052, 2A12)

Stainless Steel (201, 303, 304, 316/316L, 430)

Mild Steel (1018, 1045, A36)

Alloy Steel (4340, 4140, 1215)

Tool Steel (A2, A3, D2, H13, O1, S7)

Spring Steel

Titanium (TC4)

Brass

Copper

ABS

Polycarbonate (PC)

Nylon

Polyethylene (PP)

PEEK

Bakelite

FR4 Glass Epoxy

Carbon Fiber Prepreg Plate

*Technical Data Sheets provided for reference under each material type.

Note: All data is for reference only. Zacarias Engineering LLC does NOT guarantee results.